In a Nutshell:

- Lee Matteson and Rose Schick determined differences in cost and labor for strawberry bed establishment using two methods: biodegradable plastic and a matted row of mulch.

- The farmers tracked labor, expenses, yield, and revenue during the establishment year and the first year of harvest.

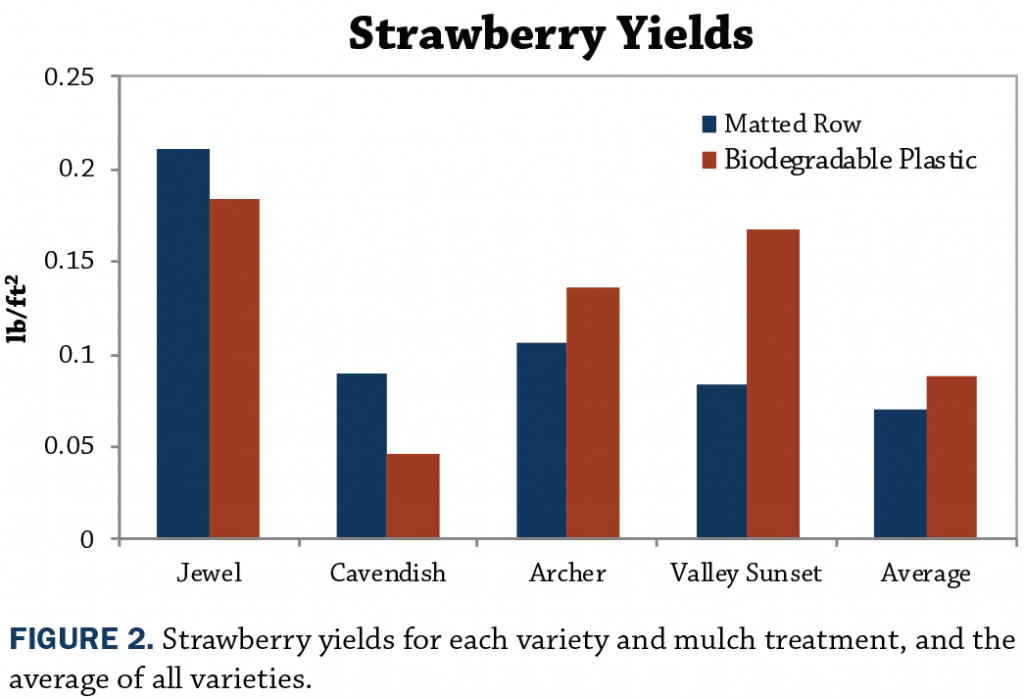

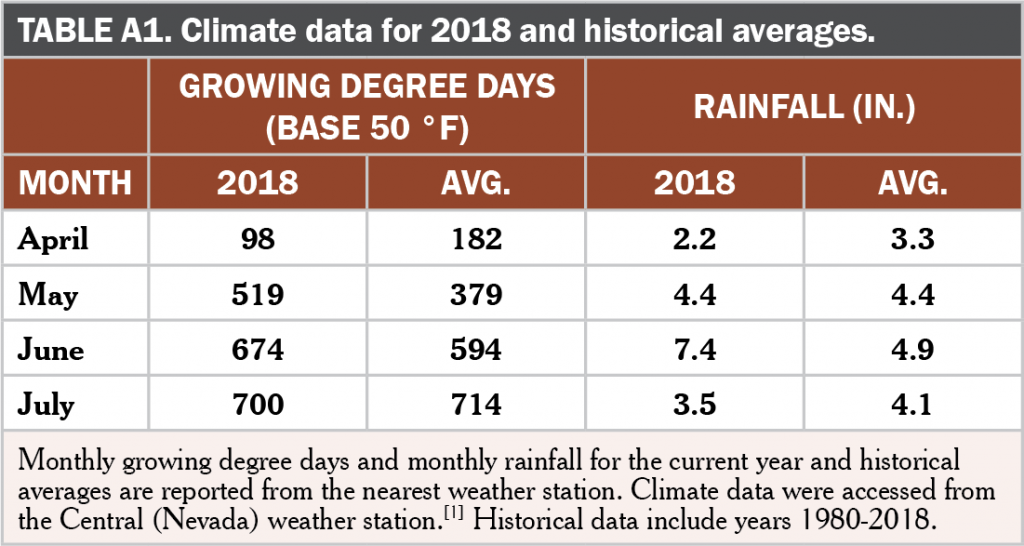

- Strawberry yields were low in 2018 due to extreme heat in May.

- Even with poor yields, the biodegradable plastic system provided a net profit of $0.66/lb. The straw mulch system had a net loss of $0.50/lb.

- The strawberry variety Cavendish performed poorly in the heat.

Background

Locally-grown strawberries are in high demand at markets, but the time and labor demands of growing them make strawberries a trickier crop to manage than many realize. The plants require a year of establishment before the first harvest; preventing competition from weeds is critical. In this trial, Lee Matteson and Rose Schick of Nevada compared the enterprise budgets for strawberries under two methods of establishment: matted rows mulched with corn stalk mulch, and planted into biodegradable plastic mulch. For two years, the farmers tracked expenses, labor, yield and revenue on four varieties of strawberries to determine which establishment system was better for their farm.

Objective: Compare labor, yield, and profitability of strawberries under two plant establishment systems.

Methods

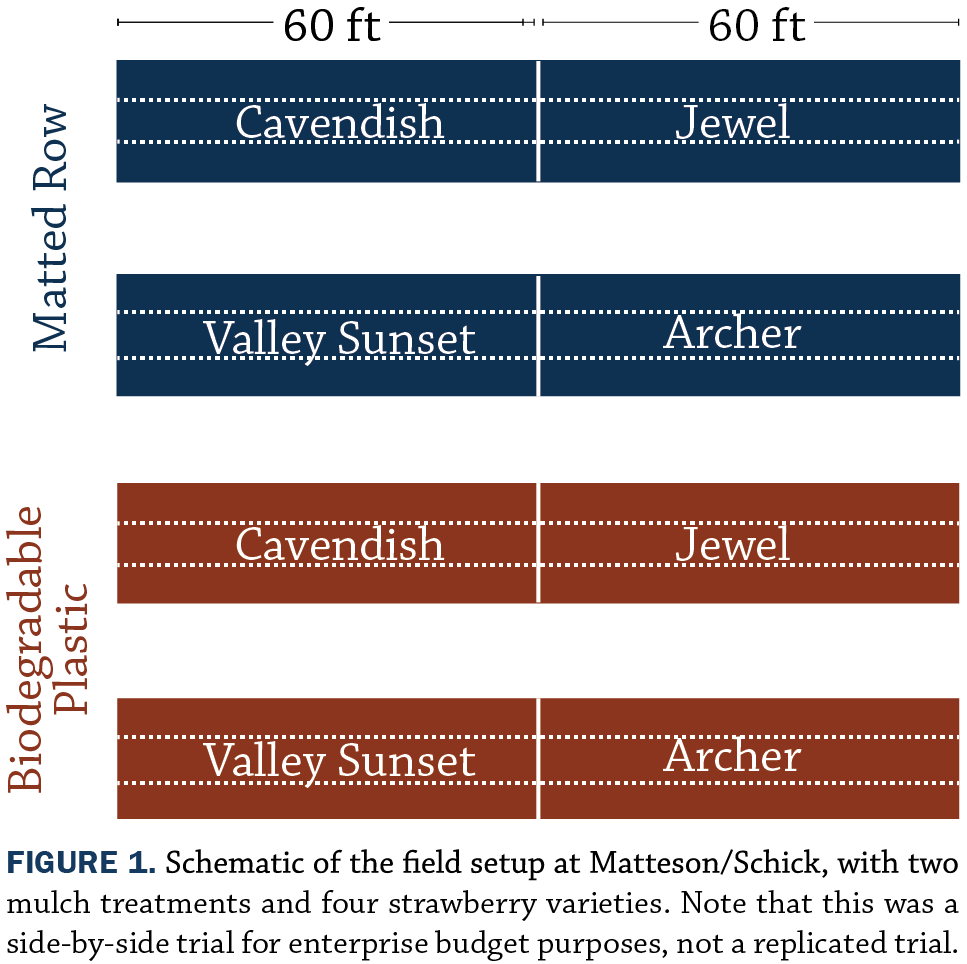

This project compared enterprise budgets of strawberry production under two establishment systems and was conducted by Lee Matteson and Rose Schick on their farm near Nevada. The farmers planted four varieties of strawberries – Cavendish, Valley Sunset, Jewel and Archer – in 60-ft long beds under two different mulch systems used for weed suppression. One set of strawberry plants was planted into biodegradable plastic mulch, the other set of strawberry plants was planted into cornstalk mulch and established as a matted row, as shown in Figure 1.

Strawberries were planted on Apr. 20, 2017; with their first bearing year in 2018. Under both treatments, strawberries were planted in double rows, with 6 in. between plants within the row and 12 in. between rows. The sets of double rows were spaced 4 ft apart.

In addition to yield data, Matteson and Schick tracked labor hours by task, expenses and revenue to compare enterprise budgets for strawberry production under both systems. Data was sent to Practical Farmers of Iowa for analysis.

Results and Discussion

Unfortunately, 2018 was a very poor strawberry season due to extreme heat in May (Table A1; yields by variety under each establishment system are shown in Figure 2. Typically, strawberry picking lasts five to six weeks; the 2018 season last only two weeks, and the farmers harvested about 15% of what they normally expect. According the Schick, Cavendish did not handle the heat at all, and fruit became unsellable. Jewel appeared to perform the best. Because the varieties were not randomized and replicated, statistical means comparisons could not be done on this trial. Overall, the plants established on the biodegradable plastic produced 10 pounds more than the matted row. Though it was not a good year to track yield information, the labor and expense data was still very informative to Matteson and Schick, moving forward.

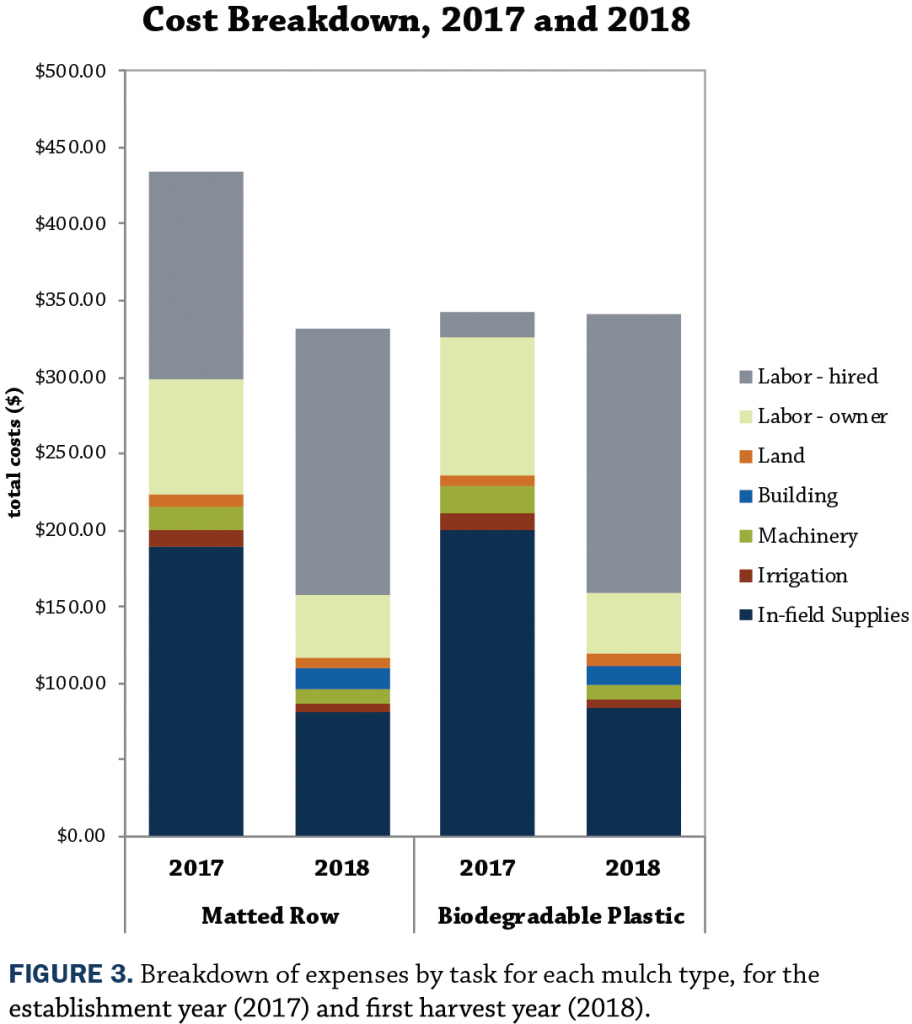

Even with the unfavorable weather, the single season of strawberries picked on the biodegradable plastic system did provide a positive net return of $0.66/lb over the two years of expenses, as shown in Table 1. The matted row resulted in a net loss of $0.50/lb. This was due to more labor costs – particularly in the establishment year – and slightly lower average yield across varieties.

Figure 3 shows the breakdown of expenses for the establishment year (2017) and first year of harvest (2018). In 2017 the matted rows required nearly twice the labor cost of the biodegradable mulch rows. This was impactful, as labor accounted for 48% of the matted row system’s expense during the establishment year (labor was 31% of the biodegradable plastic system’s expense during 2017). In 2018 total expenses between the two establishment systems differed by only $1.50. Though 2018 expenses were nearly identical, with higher expense over the two years and slightly lower fruit yield in the matted row in 2018, the matted row system was less profitable.

Conclusions and Next Steps

Inclement weather – the combination of a very hot May followed by a very wet June (Table A1) shortened the strawberry harvest in 2018. Because of the irregular season, the results of this trial were not definitively conclusive for Matteson and Schick. The biodegradable plastic system was more profitable in 2018, and had a more efficient harvest due to the system’s compact rows. Said Schick, “In general, the plastic kept a more compact row as the plastic prevented runners from suckering in the first year. The matted row spread out, making for more plants but harder to pick as the row became too wide and ran into the bed next to it. The black plastic had less weeding the first year but by second year the biodegradable plastic was gone and labor needed for weeding was the same in both types.”

A more traditional harvesting season might have provided a different yield portrait of the two systems. Would more suckering plants, widely spread in the rows, increase yield over six weeks of picking? Or are labor-hours worth more during picking season, placing priority on efficient harvest?

Appendix – Weather Conditions

References

- Iowa State University. Iowa Environmental Mesonet. https://mesonet.agron.iastate.edu/ (accessed March 2019).