Sweet Potato Enterprise Budgets: What are the costs and returns of this popular CSA crop?

This project was funded by Ceres Trust.

Why is this important?

Farmers in PFI’s Cooperators’ Program have previously conducted enterprise budgets on cucumbers[1,2] and cherry tomatoes[3], and for this project, turned their attention to another charismatic but labor-intensive crop: sweet potatoes. An enterprise budget for sweet potatoes from Iowa State University reports a net annual return of less than $0.01/lb.[4]

Sweet potatoes are a popular fall storage crop, and as part of the morning glory (Convolvulaceae) family offer a nice agronomic and culinary alternative to winter squash (Cucurbitaceae). But because they are both a vining crop and a root crop improved by curing, sweet potatoes can present challenges for weed management and harvest and washing, depending on soil conditions.

Who participated and what did they do?

Kate Edwards, Emily Fagan, Jordan Scheibel and Jon Yagla tracked expenses, labor, yields and revenue for sweet potato production on their farms during 2019. From this information, we calculated net income. Each farm planted and managed sweet potatoes according to their own timing, markets and preferred practices, which are detailed in Table 1. Each of the farms grew sweet potatoes primarily for CSA, and harvested by hand with broadforks and digging forks. Data collected from each farm was standardized to provide insight into costs, labor and returns at each farm. All farms grew sweet potatoes in the field; Fagan also included an enterprise budget for sweet potatoes in a high tunnel. Two farmers, Edwards and Scheibel, used black plastic to control weeds under their sweet potatoes.

“I like growing sweet potatoes and have had decent success with them over the years for my CSA, but I’ve been unsure about their economics on my small farm, growing only a few hundred row feet of them and harvesting by hand,” said Jordan Scheibel of Middle Way Farm in Grinnell. “By doing an enterprise budget, I hope to get a better understanding of my costs associated with sweet potatoes so I can make an objective analysis of their profitability. It doesn’t mean I will stop growing them if they’re not very profitable, but it will mean I will make sure to limit the amount I grow to just what I think I need for CSA.” Other farmers were similarly curious about the financial return on their labor, how their production practices compared to one another, and were motivated to better use enterprise budgets as a farm financial management tool.

What did they observe?

Overview and net income

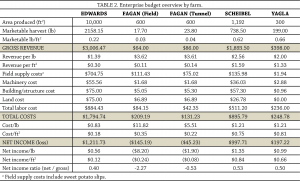

Table 2 provides yield, revenue, expenses and labor, and net income for the sweet potato crop at each farm. Revenue, costs and net income values are presented as the annual total, per pound sold, and per square-foot for each farm, to help farmers consider aspects of their pricing and return to their land area. Though it may be tempting to extrapolate these values to per acre to compare with larger farms, it is important to remember that Iowa’s market limitations and the multiple effects of economies of scale would alter the unit costs and revenue associated with any crop production. Sweet potatoes were profitable for three of the four farms: Edwards, Scheibel and Yagla, who netted between $0.56/lb and $1.35/lb. Fagan found a net loss for sweet potatoes on their farm in both the field and the high tunnel.

Production costs

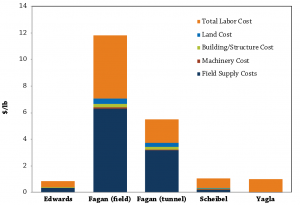

Field supplies were the top costs at Fagan’s, while labor was the top cost at Edwards’, Scheibel’s and Yagla’s (Table 2). Figure 1 considers each production cost category per pound of sweet potatoes produced on each farm.

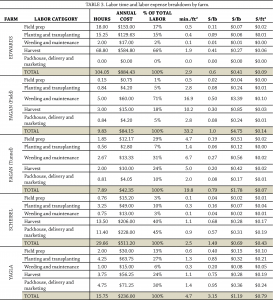

Labor

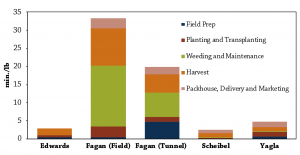

Labor was either the most expensive or second-most expensive cost at all farms (Table 2). A breakdown of labor expended at each farm is provided in Table 3. In general, harvest accounted for most or much of the labor expended at each farm. Production practices, machinery, yield and the level of washing and curing a farm does impacts how the labor time is distributed on a farm. For example, high yield years will take longer to harvest overall, but will be harvested per pound at a faster rate. Black plastic likely reduces weeding time, but would require different labor for field prep and clean-up. Properly allocating labor expenses like marketing, tractor maintenance, and employee management to these enterprise budgets is still a work in progress, but these values represent the farmers’ records and, on occasion, calculated estimates. Figure 2 shows the breakdown of labor (minutes) spent on each farm per pound of sweet potatoes produced.

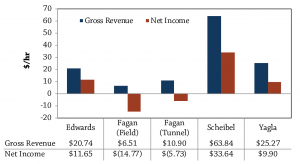

Figure 3 provides the gross revenue and net income per labor-hour by farm. Here we see that each farm generated positive gross revenue per hour of labor expended, but that only Edwards, Scheibel and Yagla scored positive net incomes per hour of labor expended to produce sweet potatoes in 2019. By these numbers, we can say that these three farms profitably used their time. But in Fagan’s case, producing sweet potatoes was not a profitable use of time in the field and high tunnel in 2019.

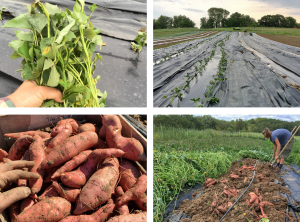

Sweet potato production on Kate Edwards’ farm in 2019. Clockwise from top left: Sweet potato slips prior to planting on June 15; farm crew planting into black plastic on June 15; a worker opens soil with a broadfork during harvest; harvested sweet potatoes.

What did we learn?

- Sweet potatoes were profitable on three of the four farms, providing a net income range of $0.56–$1.35 per pound at those three farms.

- Sweet potatoes also offered a profitable return to labor on three of the four farms, ranging from a net of $9.90/ labor-hr to $33.64/labor-hr.

- After reviewing the numbers, Fagan and Yagla have decided not to continue growing sweet potatoes in 2020, and to instead focus their attention on more profitable crops.

“This is why we do enterprise budgets – so we know,” Fagan said. “Based on these numbers, we aren’t doing sweet potatoes anymore.”

Yagla noted the amount of labor when deciding to discontinue offering sweet potatoes in his CSA. “I learned a great deal about how much goes into growing sweet potatoes! There’s often a lot more labor going into a crop than expected.” Looking to the future, he added: “I am inspired to try more enterprise budgets in the future on other crops.”

“Based on demand and knowing my sweet potato crop is profitable, I will be doubling my crop next year,” Scheibel said. “While I found the process very challenging and discouraging at times, the end product was both useful to my operation and very satisfying, showing that I can indeed grow sweet potatoes profitably even though they are on a small scale and are largely non-mechanized.”

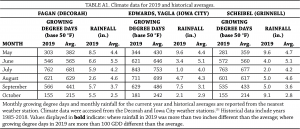

Appendix – Weather Conditions

References

- Kolbe, L., E. Johnson and J. Libbey. 2016. Enterprise Budget for Cucumbers, Year 2. https://practicalfarmers.org/research/enterprise-budget-for-cucumbers-year-2/ (accessed October 2020).

- Kolbe, L., E. Johnson and J. Libbey. 2015. Enterprise Budget for Cucumbers. http://practicalfarmers.org/farmer-knowledge/research-reports/2015/enterprise-budget-for-cucumbers/ (accessed October 2020).

- Kolbe, L., A. Franzenburg and E. Johnson. 2017. Enterprise Budget for Cherry Tomatoes. Practical Farmers of Iowa Cooperators’ Program. https://practicalfarmers.org/wp-content/uploads/2018/11/17.H.Enterprise_Budget_Cherry_Tomatoes.pdf (accessed October 2020).

- Coll, E. and C. Chase. 2019. Iowa Fruit and Vegetable Production Budgets. Iowa State University Extension. File A1-17:13. https://www.extension.iastate.edu/agdm/crops/pdf/a1-17.pdf (accessed October 2020).

- Iowa Environmental Mesonet. 2019. Iowa Environmental Mesonet. Iowa State University Department of Agronomy. http://mesonet.agron.iastate.edu/ (accessed October 2020).