Compost heat is going underground…

The days are shorter, the nights are cooler, the compost at TableTop Farm is still steamy warm. The compost heat extraction system (featured in the Fall 2013 issue of The Practical Farmer and on the PFI Blog) is in its final phases of construction and will be ready to begin moving heat to the high tunnel this weekend, providing a “soil heat bump” during cold snaps.

TableTop farm and PFI staff worked with Rich Schuler to install the pex tubing under the soil and insulate the perimeter. After the tubing was in place, TableTop’s high tunnel was moved to cover the area. For the upcoming fall growing season, Rich and TableTop staff will be able to compare productivity of the “heat bump” zone to the unheated control zone in the high tunnel; the “heat bump” zone accounts or 10% of the high tunnel’s growing space.

Sally Gran, the owner of TableTop, has planted spinach, lettuce, and baby brassica greens for fall CSA shares and the winter farmers market in Ames (at Wheatsfield Coop November 16).

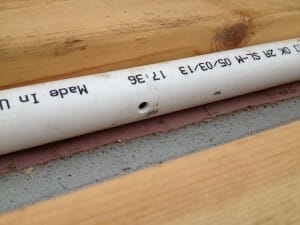

Interior of the compost compartment in the unit, and close up of the PVC in the floor. Air is pumped through the holes in the PVC. The air heats as it moves through the compost. The warmed air heats the water tanks, which pump through the pex tubing. The third picture is the curing compost and a manure pile waiting to be incorporated.

The “heat bump” area, insulated with foam board 18″ deep, measures 13’x22′, roughly 10% of the 96’x30′ high tunnel. The PEX under the soil is 1/2″, connected to the compost unit by insulated 3/4″ PEX.

The trench running from the high tunnel to the compost unit with 3/4″ insulated PEX. The next picture is a close up of the hook-up between the 3/4″ PEX and the 1/2″ PEX inside the high tunnel. The third photo above is the high tunnel moved over the top of the heat bump area, where it will stay for the winter.