Workshop Recap: Tractor Operation, Safety and Maintenance with Shane LaBrake

“What is entrusted to us, we should care for.”

This stewardship ethic seeped into each unit of Shane LaBrake’s 2-day tractor workshops. Being good stewards of the land, our bodies, our workers’ health, and yes, the machines themselves, he argued, builds an environment where fewer resources and time are needlessly wasted. He also reminded workshop attendees of Neil Young’s prophetic album title: “Rust Never Sleeps.”

The largest takeaway for the attendees at the workshop were:

1. Tractors are powerful tools – use them professionally. Use ROPS, wear a seat belt, tell someone where you are, wear protective equipment, follow safe operating practices.

2. RTFM – Read The “Freaking” Manual. There are over 240 makes of tractor and over 9,000 models; knowing yours is what matters.

3. Routine maintenance and daily pre- and post-use maintenance checks save time and money. (Shane provided a list of these checks, which he encourages farmers to keep visible on the tractor).

4. Each attendee felt more confident in their ability to continue learning how safety and effective operate and maintain a tractor. And they felt empowered by their new knowledge to be more discerning and confident when shopping for tractors and implements.

Workshop attendees learning about tire types and safety features on a New Holland TN65.

The first workshop, March 17-18, was hosted by Eric and Ann Franzenburg, near Belle Plaine. Each workshop was capped at 12 attendees, to provide a more thorough learning experience for each person. Though the weekend was chillier than hoped for, attendees layered-up and worked primarily with a New Holland TN65. Eric also had a Case IH 3150 and McCormick CX105 nearby, for comparison.

Attendees take notes inside the shop at Eric Franzenburg’s parents’ farm.

Checking the oil – part of Shane’s recommended daily pre-operation maintenance routine.

At the Ames-based workshop on March 20-21, attendees gathered at the new PFI office each morning, and moved to the ISU Agronomy and Engineering shop in the afternoon. Shane travels in a 4-wheel drive utility van, which allows him to bring an extensive assortment of tools, engine parts and products, which he uses to demonstrate engine function and discuss maintenance. Continue scrolling down to see more photos from the workshop.

Shane discusses how the timing gears serve the engine.

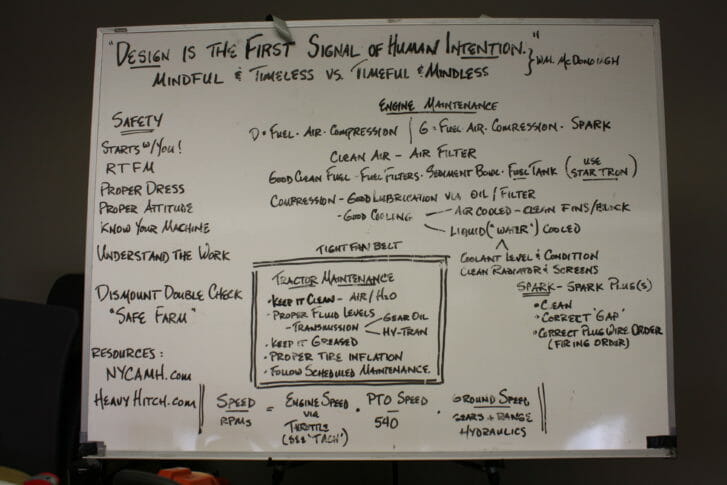

Shane’s 2-day workshop distilled to a single white board.

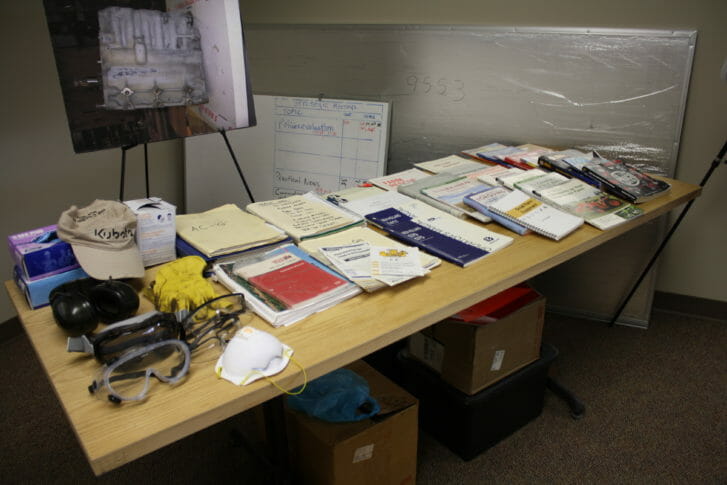

Some of Shane’s instructional materials, including carborators, camshafts, flywheels, spark plugs and pistons. Also visible are some of his favorite products and tools for tractor maintenance.

Safety equipment, manuals and books that Shane recommends.

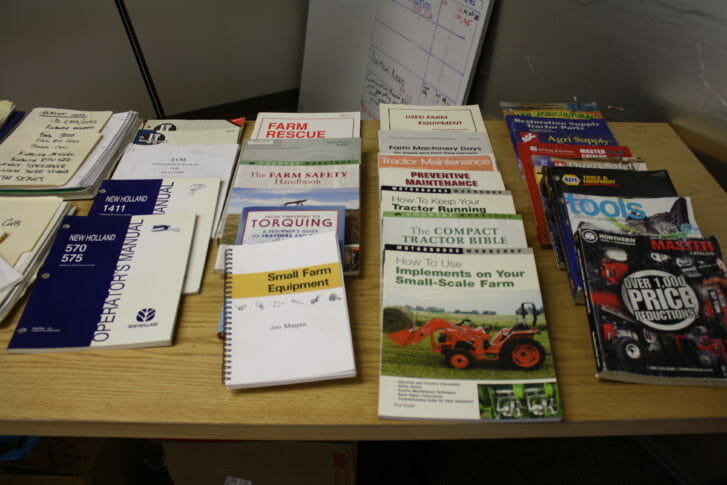

Some of the most useful textbooks Shane has are from old Motorbooks or vo-ag classes.

Roxanne Dunn watches Kate Solko attach the 3-point hitch.

Julia Slocum screws on the oil drain plug on an International Harvester 140 offset tractor.

Workshop attendees check the oil on a John Deere 5105 in Ames. Special thanks to the ISU Horticulture Farm for bringing over three tractors for the workshop!