Using Custom Equipment to Weed and Seed Legumes on an Organic Farm

John and Halee Wepking operate Meadowlark Farm and Mill in Ridgeway, Wisconsin. The farm is organic certified, consisting of 150 fields on 900 acres in the driftless region. Previous owner Paul Bickford inherited the farm in 1978 when it was a confinement dairy operation. In 1992, it was transitioned to grass-fed dairy, focusing on rotational grazing. The farm was then converted to an organic grain farm in 2012.

After leaving work in the culinary world in New York and returning to John’s home farm in Wisconsin, Halee and John ventured to find work in the organic food and farm realm.

By chance, they found that Paul was seeking help and hoped to mentor beginning farmers. The three of them connected, and in 2015, John and Halee started working on Paul’s farm.

Paul Bickford mentored Halee and John on Meadowlark Farm as they began their years-long process of transferring ownership.

When Halee and John first came onto the farm, it was primarily continuous corn and soybeans with some oats and barley as a nurse crop for alfalfa. Until that time, cultivation had been a widespread practice on the farm. To help prevent soil erosion and reduce tillage, they suggested using more small grains in rotation.

The Wepkings now own and run Meadowlark Farm following Paul’s death in 2022. The farm has an elaborate crop rotation system in place to grow a wide variety of food-grade small grains for the mill.

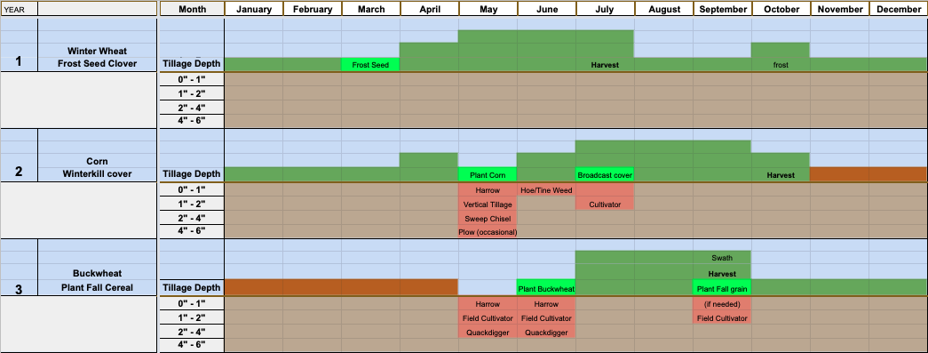

The farm does still grow corn and soybeans, but they are no longer grown back-to-back. John shared the rotational practices of Meadowlark Farm, their process for frost-seeding clover into small grains and more in a shared learning call in March.

Finding a Beneficial Rotation

John admits that the farms’ crop rotation is not set in stone, but rather one that balances the needs of each field. This includes everything from labor and machinery availability, weather, farming on contours and maintaining shallow tillage.

John says, “There are certain tried and true crop sequences that we really like. For example, growing buckwheat into winter wheat and then frost-seeding clover followed by corn. It’s a nice minimum tillage crop sequence and we’re still able to grow three productive crops.”

Right after corn, John seeds a succotash mix of oats and peas. “Last year, we did 40 acres of oats, barley, 40-10 peas and flax.”

John follows this with a cover crop mix of legumes and brassicas. He prefers non-grass cover crops, that will winter kill, but leave a decent residue come spring. This green manure mix will allow nitrogen to be available in the soil when spring wheat is planted.

Wheat is one of Meadowlark Farm’s most versatile crops. “Wheat is a wonderful crop because it free threshes, and if you grind it, you can make a useful, universally applicable food product, so it’s a great grain to value-add in your rotation,” says John. “It’s also nice that you can spring seed it or use it as a winter annual, in the case of winter wheat.”

John’s spreadsheet cleverly used to track and plan for field rotations across several years. (This image doesn’t show all the years and crops in Meadowlark’s rotations.)

Frost-seeding clover and interseeding alfalfa with a modified tine weeder

To build nitrogen in the soil with small grain crops, the Meadowlark team frost-seeds red clover with their custom 30-ft Treffler tine weeder mounted with an air seeder. Frost-seeding begins in late winter or early spring and occurs in the early morning hours while the ground is firm.

“We pretty much eyeball it with our frost-seeding, but compared to a four-wheeler with a spin seeder, we definitely get a more uniform seeding rate over those 30 feet.”

John and Halee’s 30-ft Treffler tine weeder mounted with an air seeder used for frost-seeding red clover.

John is adamant that when frost-seeding with a tine weeder, it’s best to gently float the tines above the soil and make sure they are not scratching the soil. When the ground is so cold, scratching the soil could put too much stress on the cables and springs of the tine weeder. He adds, “But when we are seeding alfalfa or hay into spring wheat or oats, then we are doing a weed control pass with the tine weeder and scratching the surface while also blowing the seed on.”

When all spring seeding is done, John removes the air seeder from the tine weeder. The extra weight can put a lot of stress on the machine, especially since Meadowlark farm has so many hills and curves.

He continues to use the tine weeder as needed with spring-seeded small grains, corn and soybeans, but notes that it is not always the best method for weed control.

“In high residue environments, it’s pretty useless because it just becomes a big garden rake and fills up with residue,” says John. John also says that in those environments, or when the soil is crusty, a rotary hoe is a much better option for controlling weeds.

Additional Resources

Subscribe to our monthly newsletter, Small Grains News.

Learn more in this video about tine weeders and organic weed control.

Check out this blog recapping a 2018 shared learning call about frost-seeding clover into small grains.

Find out more about Meadowlark Organics on their website!