In a Nutshell:

- Lee Matteson tested five varieties of romaine lettuce in a hydroponic setup.

- Matteson carried out the trial over three successions from February through June.

- Matteson was especially curious to learn of varietal tolerance to climate across the successions.

Key Findings

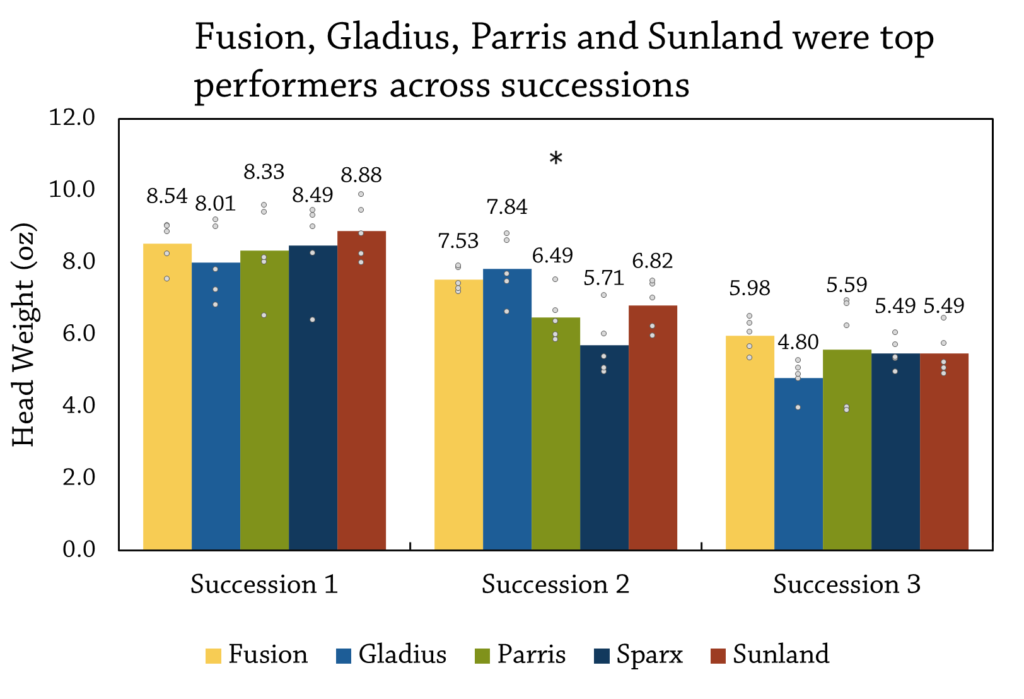

- Fusion, Gladius, Parris, and Sunland were top performers across successions; all these varieties were statistically equal to one another in head weight.

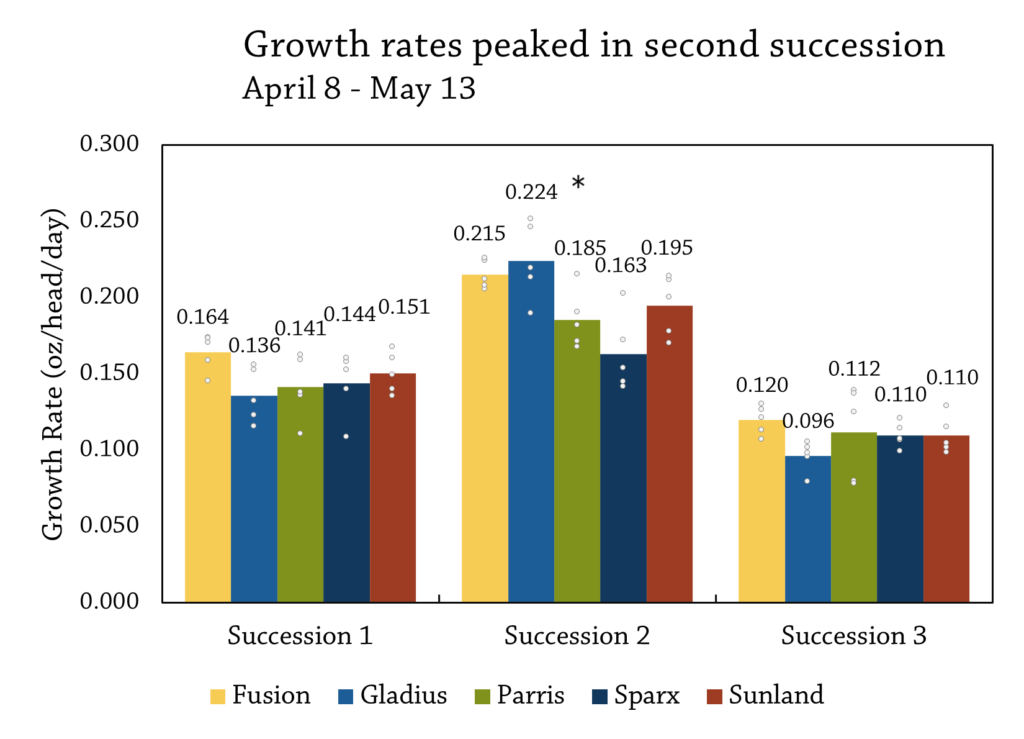

- Lettuce growth rates peaked in succession 2 (Apr. 8-May 13); lettuce varieties reached a marketable size and quality much faster than the other successions.

Background

Hydroponics is the technique of growing plants in nutrient solution instead of soil. Hydroponically-grown plants often have higher rates of growth than conventionally-grown plants, but all plant growth rates depend on the environmental conditions [1]. In soil, plant-available nutrients are dissolved or suspended in the water in the complex matrix of the soil, and plant roots absorb these nutrients from the immediate soil environments of their surface areas. In hydroponics, prepared mixtures of nutrients are dissolved in solutions in which the plant roots grow. Because the nutrients in the solution are being constantly refreshed by fluid currents of solution, hydroponically grown plants invest less resources in nutrient acquisition in comparison with soil-based systems, where plant uptake of nutrients leads to local depletion. Soil-grown plants grow more extensive root systems and more root hairs as a strategy to deal with local soil nutrient depletion. The availability of water and nutrients, along with the generally benign growing conditions in the greenhouses where hydroponics systems are set up, explain the difference in growth rates between hydroponically- and soil-grown plants [1].

Growth in hydroponic systems is easier for plants, but it also confers some advantages to their human caretakers. Without soil, growers have more flexibility to control the environment around the plants: water and nutrients are abundantly available to plants without competition from weeds, indoor growth means that temperature, lighting, and insects can be controlled. Matteson has high tunnels and greenhouses where he grew greens in the shoulder seasons in the ground and started transplants for summer and grew tomatoes and cucumbers in high tunnel soil. Disease outbreaks, especially powdery mildew, motivated him to try something new. He began experimenting with hydroponic green production and growing his tomatoes in bags of fertigated media. Matteson has found that the modular layout of his hydroponic setups enables multiple generations of plants to be grown in quick succession: he moves germinated seedlings in their media cube into the setup, lets them grow, harvests, scrubs out the setup, rinses, and repeats.

There are multiple controlled environment agriculture (CEA) technologies that can enable quick successions. Hydroponics and fertigated greenhouses or heated high tunnels all have many of the advantages listed above in common. Choosing which system is best for a given producer requires a thorough analysis of the systems’ advantages and disadvantages, and how they interact with the resources, technology, and expertise available. To list some of the possible tradeoffs: certain diseases and salts that can build up in always-covered soils are less problematic for hydroponics, where solution ion concentrations are monitored regularly to maintain optimal nutrient availability. Hydroponic systems are vulnerable to certain water-borne pathogens that cannot move as quickly through soil. The fluid volumes and moving parts of a hydroponic system require more climate control in the winter in the Midwest than high tunnel soils that might be allowed to freeze.

Matteson grows romaine lettuce hydroponically in a heated high tunnel throughout the winter in Nevada (central Iowa). The heater keeps the temperature survivable for the plants through the winter, but there are no lights, and growth is therefore limited by the short daylengths. Cooler ambient temperatures also limit growth rates, and the economics of heating the greenhouse must be balanced with salable produce. As temperatures rise in the spring, heat concentrates in the greenhouse which might stress the plants to bolt and conclude production. Matteson wanted to test a range of romaine lettuce varieties across time from February through June, with the hopes of identifying options that performed well under the more difficult climatic conditions at either end of that timeframe.

CEA provides several advantages for information gathering through on-farm research. Short generation times, high levels of uniformity in growing conditions across and between replicates, and a moderated influence of weather are all characteristic benefits of doing research in a controlled environment, and Matteson put all three to use in designing his romaine variety trial.

Methods

Lee Matteson’s nursey greenhouse. In addition to herb and microgreen production, this heated greenhouse is where the seeds are germinated before being transplanted into the hydroponic system. Seeds in media cubes are visible in various stages of germination in different trays. Photo taken March 11, 2025.

Design

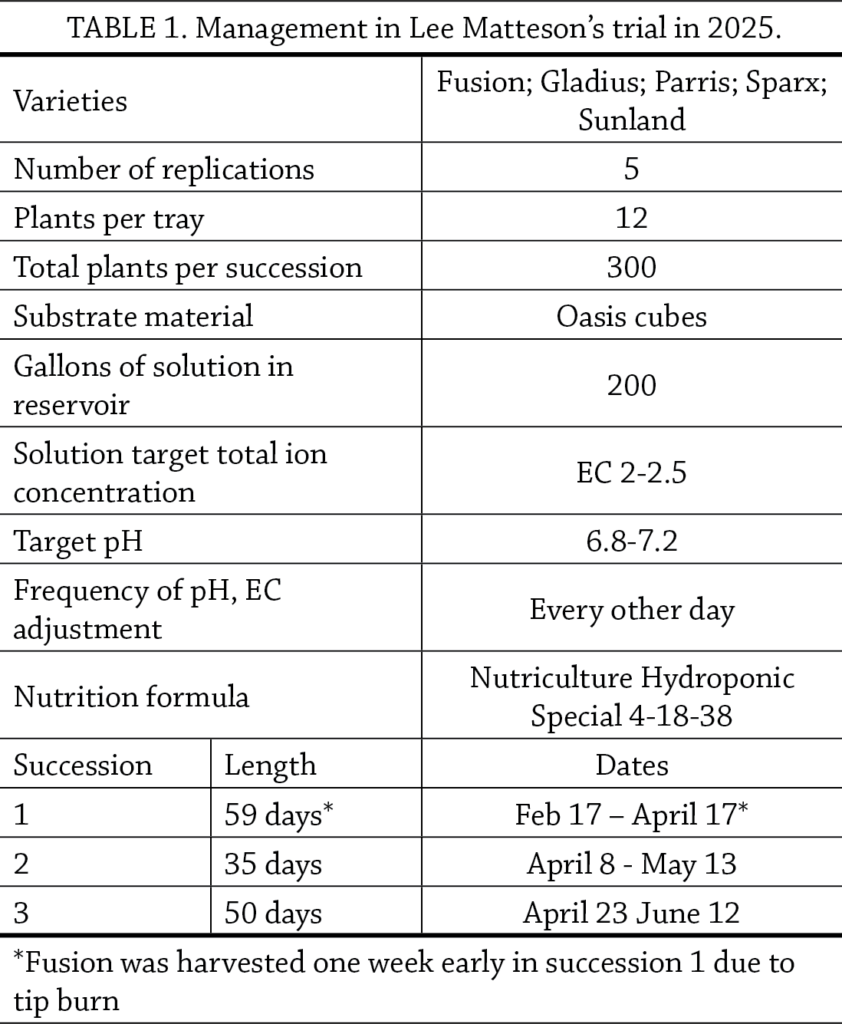

Mattson selected five varieties of romaine lettuce to trial in Spring 2025. The five varieties were Fusion, Gladius, Parris, Sparx, and Sunland. For detailed management information, see Table 1.

Lettuce plants were sprouted in the nursery for two weeks before being transplanted into the nutrient-film-technique (NFT) setup. Twelve plants, all the same variety, were transplanted into each NFT tray. Each tray was an experimental replication.

Three successions were grown. Harvest was determined by when plants reached marketability. This led to varying numbers of growing days: S1 59 days, S2 35 days, S3 50 days. The first succession was planted Feb. 17 and harvested Apr. 17. The second succession spanned Apr. 8-May 13. The third succession was planted Apr. 23 and harvested June 12. Management details are provided in Table 1. The same set of five varieties was grown in each succession, so results are comparable across successions.

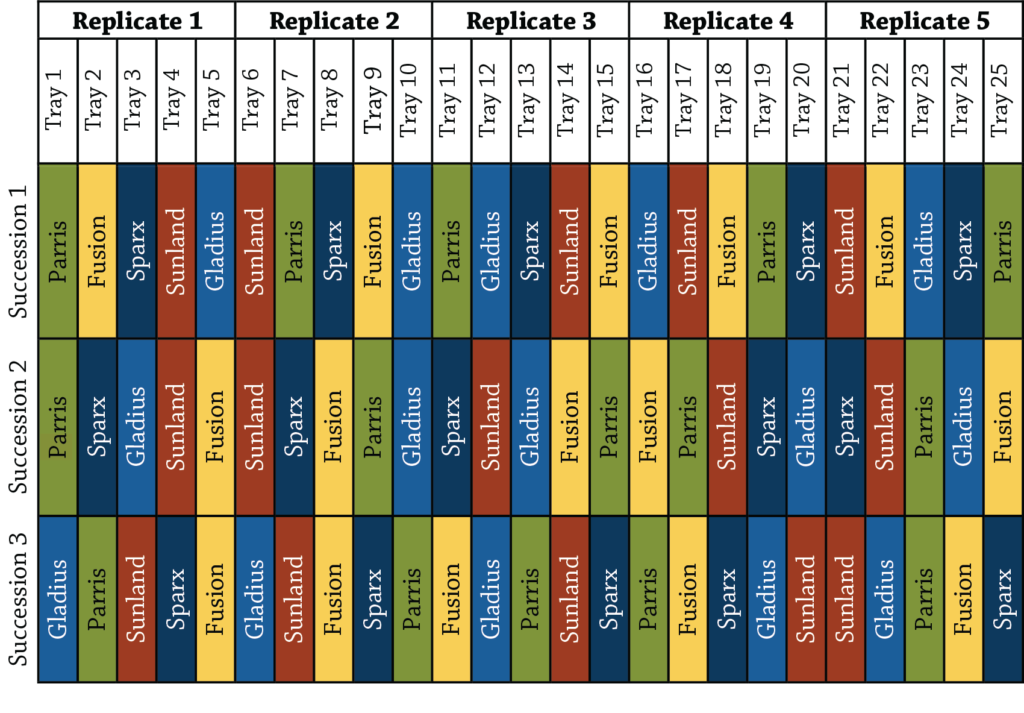

Matteson grew five replicates of the five varieties in each of the three successions. The random arrangement of varieties within each replication is shown in Figure A1.

Measurements

Matteson counted the number of marketable lettuce heads he harvested and measured the yield of each tray by weight. These measurements, along with his management data on planting and harvest dates, allowed us to calculate average head weight and average growth per day.

Data analysis

We used an Analysis of Variance (ANOVA) and Tukey’s honest statistical difference (HSD) post-hoc test at a 95% confidence level to determine whether there were significant differences between varieties and successions. Both variety and succession were analyzed as treatment variables. A statistical difference between treatments means that one treatment outperformed the other and the farmer can expect the same results to occur 95 out of 100 times under the same conditions. We can perform this analysis because Matteson used completely randomized and replicated experimental designs in each succession.

Results and Discussion

Fusion, Gladius, Parris, and Sunland were top performers across successions; all these varieties were statistically equal to one another in head weight (Figure 1). In succession 2, Sparx produced the smallest heads. Average head weight across varieties decreased from 8.5 oz in succession 1 to 6.9 oz in succession 2 to 5.5 oz in succession 3 (Figure 1). This was due to a shortening of the growth period for the second succession and heat stress during the third succession (Table 1). Although there was no statistical difference, Gladius was numerically the smallest variety in succession 3.

Figure 1. Head weights in Lee Matteson’s 2025 hydroponic romaine variety trial. Dots on bars indicate the yield per head of individual replicate trays within each variety and succession. Succession 1 lasted 59 days, Feb. 17 – Apr. 17; succession 2 lasted 35 days, Apr. 8 – May 13; succession 3 lasted 50 days, Apr. 23 – June 12. Asterisk (*) over succession 2 indicates a statistically significant difference between varieties was detected. In this case, Sparx produced the smallest heads.

Gladius was developed by Rijk Zwaan in the Netherlands and sold as “suitable for hydroponic production”, the only variety tested in this trial that was developed at least partially for hydroponic production [2]. Interestingly, its performance was not statistically distinguishable from the three other top-performing varieties (Fusion, Parris, Sunland).

Fusion was among the highest-yielding varieties in all successions. However, in the first succession it had issues with tip burn, which caused those plants to be harvested a week earlier than the other varieties (Table 1). Tip burn is exacerbated by low temperatures, which limit plants’ transpiration and nutrient mobility [3], [4].

Succession 1 scored the highest head weights and lasted 59 days for an average growth rate of 0.147 oz/head/day (Figure 2). Succession 2 lasted only 35 days but boasted the top growth rate of 0.198 oz/head/day. Though yields were smaller in succession 2 than in succession 1 (Figure 1), Matteson was pleased with how quickly the plants in succession 2 reached a satisfactory size that he could market (24 fewer days than in succession 1). There seems to be a ‘Goldilocks’ period in April and May (when succession 2 occurred) when light pours in, but the temperatures are not too high for the greenhouse to vent out. In succession 3 (Apr. 23 – June 12), the heat in the greenhouse reached levels that stressed the plants and started causing them to bolt. Growth rate slowed to 0.109 oz/head and Matteson harvested at 50 days; earlier than he otherwise would have, salvaging marketable, if small, heads with poor quality. Fusion, Gladius, Parris, and Sunland had the highest growth rates, all statistically equal, in all three successions (Figure 2). In succession 2, Sparx grew the slowest.

Figure 2. Average daily growth per head at Lee Matteson’s 2025 hydroponic romaine variety trial. Dots on bars indicate the average daily growth of individual replicate trays within each variety and succession. Succession 1 lasted 59 days, Feb. 17 – Apr. 17; succession 2 lasted 35 days, Apr. 8 – May 13; succession 3 lasted 50 days, Apr. 23 – June 12. Asterisk (*) over succession 2 indicates a statistically significant difference between varieties was detected. In this case, Sparx had the slowest growth rate.

Closeup of part of Lee Matteson’s nutrient-film-technique (NFT) hydroponic setup. The black on the inside of the PVC collection tube is algae. Algae grows wherever there are water, nutrients, and light, and can affect nutrient use efficiency but generally does not hurt plant quality. Photo taken March 11, 2025.

Conclusions and Next Steps

Matteson will continue offering diverse greens in all seasons, but this data will help inform his selections in his hydroponic setup. He wrote that “I plan to continue growing all varieties as each has a place throughout the seasons but probably increase the amount of Sunland that I grow as it seems to be a decent head size and overall good yielder”. He is also interested in expanding and improving his hot-weather production by installing retractable sunshades in his greenhouse.

Appendix – Trial Design and Weather Conditions

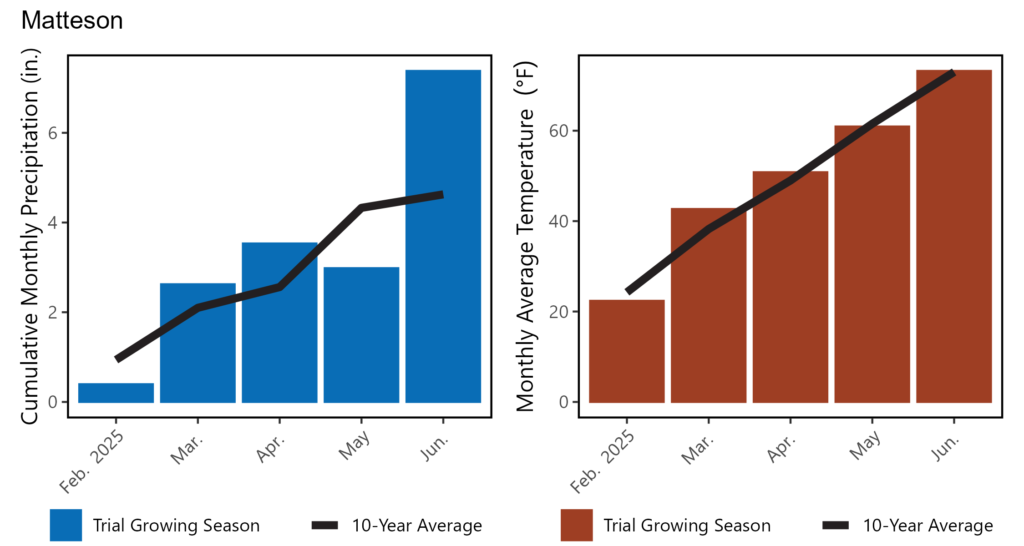

Figure A2. Modelled mean monthly temperature and rainfall (outside the greenhouse) at the trial site during the study period and the ten-year historic averages. Data is from the NasaPOWER climate dataset [5], [6].

References

[1] G. Lages Barbosa et al., “Comparison of Land, Water, and Energy Requirements of Lettuce Grown Using Hydroponic vs. Conventional Agricultural Methods,” Int. J. Environ. Res. Public. Health, vol. 12, no. 6, pp. 6879–6891, Jun. 2015, doi: 10.3390/ijerph120606879.

[2] “GLADIUS RZ KnoxTM | Cos Lettuce | Vegetable seeds | Rijk Zwaan.” Accessed: Sep. 22, 2025. [Online]. Available: https://www.rijkzwaanusa.com/lettuce/GLADIUS-RZ-prdLS11178-ctgCrops.lettuce

[3] V. Birlanga, J. R. Acosta-Motos, and J. M. Pérez-Pérez, “Genotype-Dependent Tipburn Severity during Lettuce Hydroponic Culture Is Associated with Altered Nutrient Leaf Content,” Agronomy, vol. 11, no. 4, p. 616, Apr. 2021, doi: 10.3390/agronomy11040616.

[4] A. Assimakopoulou, A. Kotsiras, and K. Nifakos, “Incidence of Lettuce Tipburn as Related to Hydroponic System and Cultivar,” J. Plant Nutr., vol. 36, no. 9, pp. 1383–1400, Jul. 2013, doi: 10.1080/01904167.2013.793709.

[5] A. H. Sparks, “nasapower: A NASA POWER Global Meteorology, Surface Solar Energy and Climatology Data Client for R,” J. Open Source Softw., vol. 3, no. 30, p. 1035, Oct. 2018, doi: 10.21105/joss.01035.

[6] A. Sparks, nasapower: NASA-POWER Data from R. (2024). [Online]. Available: https://CRAN.R-project.org/package=nasapower