Help grow the power of the PFI community. Donate today.

Energy

Through our Energy Program, we work with farmers to understand and reduce on-farm energy use and implement and evaluate efficient and renewable energy solutions.

The goal of Practical Farmers’ energy work is to help all types of farmers reduce their farm energy use. This begins with understanding current use, then implementing and measuring the impact of practical changes to equipment, infrastructure, inputs and management decisions. Energy projects can focus on increasing the efficiency of a specific aspect of the farm system, or can evaluate the whole farm. The energy work at Practical Farmers is shared with members and the public through research reports, field days, farmer profiles and case studies, conference sessions, the Practical Farmers blog and our quarterly newsletter, The Practical Farmer.

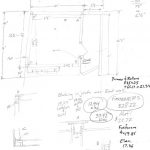

DIY Walk-In cooler Efficiency and Construction

After detailed bookkeeping and energy tracking, many fruit and vegetable growers have identified walk-in coolers as large sources of energy use. Some have used “CoolBot” technology with window air conditioning units as a cheap alternative to commercial chillers to cool their walk-ins. PFI conducted an analysis of the energy efficiency of two systems.

CoolBot vs. Commercial Chilling Systems in Walk-in Coolers Research Report

Several members decided to build walk-in coolers on their farm to save money and energy. Jordan Schiebel of Grinnell and Tony Thompson of Elkhart share information about the process.

Jordan Schiebel-Middle Way Farms

Lessons Learned at Middle Way Farm

Energy Audits and Weatherization

In collaboration with Green Iowa AmeriCorps and the University of Northern Iowa’s Center for Energy and Environmental Education, Practical Farmers of Iowa was able to provide audit and weatherization services to the farms of five members. The audits helped members save energy and energy costs associated with operating agricultural structures, including greenhouses, walk-in coolers and a chicken coop. Case studies about two of the farms can be found here:

Farm Metered Energy Analysis

How much are farmers spending on energy? What is their total energy use and carbon dioxide emissions? What difference do energy efficiency and renewal improvements make? PFI farmers are finding out as part of this project.

Contact Information

For more information about on-farm energy: contact Nick Ohde at nick@practicalfarmers.org.